The Big Dutchman Colony 2+ installation, incorporating patented communal (group) laying nests and plastic slats, contributes to the optimum production of saleable eggs from a flock. The extensive experience of Big Dutchman design engineers and application specialists in the E.U. and North America has contributed to the evolution of the Colony 2+ system, which provides the maximum number of saleable eggs by limiting downgrades from soiled shells and cracks. Reducing downgrades is an important consideration given that the average negotiated value for eggs was $7.54 per dozen over the first quarter of 2025.

The Big Dutchman Colony 2+ system contributes to high-quality eggs based on specific design features:

- The Colony 2+ nests encourage laying by providing a secure environment for hens. This potentially reduces floor-laying to a fraction of one percent in flocks that are subject to appropriate rearing and also management after transfer to the laying barn. Factors contributing to optimal production with minimal loss include compatibility between rearing and laying installations, post-transfer training of the flock, achieving uniform development and maturity at point-of-lay, and achieving an even distribution of lighting in the laying house.

|

Colony 2+ installation showing recently transferred pullets evenly distributed. House equipped with plastic slats, perches, Champion trough feeding circuits with hoppers and flat-topped nests at rear of image.

|

- The Colony 2+ nest incorporates a floor that tilts through 90 degrees during the dark period of the day or at preset intervals, excluding broody hens and preventing soiling of the plastic mat that is effectively self-cleaning with each cycle of rotation. The divided nest floor is initially raised in the center at the beginning of the closing cycle, allowing gentle roll-out onto the centrally placed egg belt. This patented feature is unique to Big Dutchman Colony 2+ nests.

Open Nest |

Closed Nest |

- The solid nest mat prevents upward movement of cold air into the nest, contributing to hen comfort and utilization.

- Big Dutchman floor barn systems can be equipped with plastic slats that potentially reduce entry accumulation of soil on the feet and litter entering the nest.

- The egg belt is located in the center of the nest bank with a short roll-out distance, protecting eggs from damage. Big Dutchman design engineers specified an extra-wide (20-inch) belt to allow separation of eggs during transport.

|

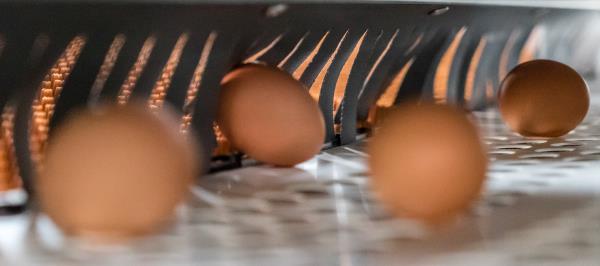

Gentle roll-out from nest on to collecting belt

|

- The EGGTRAX egg transfer unit contributes to impact-free movement of eggs from collection belts to cross conveyors or sorting tables. With the EGGTRAX Ultra option and a thicker 1.6mm egg belt, longer nest row lengths are also possible.

- Nests are available in 18-inch or 21-inch depth in either the standard or XL configuration. Depending on the arrangement of nests within the house, a single wall nest installation is available with a belt width of 9.6 inches.

Functional features of the Colony 2+ system include:

- Big Dutchman Colony 2+ nest systems are available in either single or double-tier arrangements, depending on house dimensions and flock capacity, appropriate to either new buildings or as retrofits to existing barns.

- Big Dutchman Colony 2+ systems can be supplied with either a gable roof with full-length open ridge ventilation or a flat surface to increase the available house area for the flock.

- A smooth galvanized step rail is installed at the entrance to the nests, contributing to hen comfort and the cleanliness of the nest pad.

- The frames for the Colony 2+ nest are constructed of powder-coated steel, and the legs are fabricated from stainless steel for a prolonged operating life.

- Plastic slats are fabricated from material that resists deterioration over time, and installations are supported by a substantial galvanized framework.

- All sheet metal components are powder-coated over galvanized surfaces. Nest roof tops are fabricated from laminated wood with a durable waterproof coating.

The Big Dutchman Colony 2+ system incorporates perches with roosting space conforming to both E.U. and UEP welfare standards.

Big Dutchman supplies all feeding components including outside silos, surge bins for weighing and distributing feed, and transport augers to transfer feed to hoppers within the barn.

Champion® chain feeders are installed with specially designed troughs equipped with lips that prevent wastage.

Water is supplied by suitably placed nipple drinkers with drip cups.

Big Dutchman Colony 2+ installation showing litter area, plastic slats, perches; Champion feeding circuit; nipple drinker lines;

communal nests with flat tops; LED illumination and gable air inlets. |

Big Dutchman can provide comprehensive ventilation installation, including fans, inlets, evaporative cooling pads, and controllers to optimize the environment of houses, contributing to achieving the genetic potential of flocks.

Big Dutchman design engineers can configure either new installations or retrofits by incorporating the Colony 2+ group-laying nest system into turn-key installations equipped with feeding and ventilation.

Big Dutchman technical service representatives provide guidance to producers on flock management, maintenance, and operation to optimize return on investment.

technical service representatives provide guidance to producers on flock management, maintenance, and operation to optimize return on investment.